Friday, July 23, 2021

Herculean DIY Autoformer wiring.

They say a picture is worth 1000 words... well how about how about around 180 wires and 820 solder connections? Brad from the Boston contingency wired 6 of the 28 position autoformers up for Caroll's home theater system. I often joke that more than half of the $200 autoformers I have sold sit partially wired in a box on a shelf and this picture might explain why.

Sunday, June 20, 2021

blink blink blink

I'll be he first to admit that historically I have not been a fan of either push pull or 10's and these days my daily drives are PP 300B's direct feeding stacked quad 57's and last night has me considering revisiting the 10.

The days events were to listen to cartridge variations and the mesh came in at the end of the evening as a treat for a hard days work.

Friday, September 18, 2020

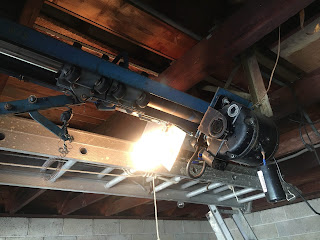

Doc Hoyer's garage door opener.

It would seem that something as trivial as a garage door opener would never find its way to these pages but often it is the trivial that gives a glimpse into who a person really was.

This seemingly Rube Goldberg approach to automatically opening a garage door is a testament to the cleverness that was Dennis R. Hoyer. I have no idea when this was constructed but given that they date back to 1926 my guess is going to Sears was not an acceptable option for Dennis.

The key to the operation is the drive mechanism and when I first looked at it I simply thought motor pulled the door open and the casters and gravity did the trick to lower the door with the motor providing some resistive force. Upon further inspection I realized something different was going on since the casters were pointed in the wrong direction.

Saturday, July 11, 2020

Maggin'

For s sense of scale here it is in relation to a charge coil for the magnet in a Sequerra ribbon.

This is a piece of more contemporary audio history. JC built the charger for Dick Sequerra to charge the magnets for his ribbon drivers.

Wednesday, June 17, 2020

R.I.P. Art

Tuesday, June 9, 2020

Doc Hoyer

Audio lost another of its treasures last week when Dennis R. Hoyer passed away in Milwaukee. If you had a vintage transformer that needed help, Doc was the person to call. On a recent trip to Milwaukee where I grew up I had the chance to visit his lab as 60+ years of his work was being dismantled. As I was admiring his winder his cousin Damian put his license plate from 1980 in my hand and suddenly I got all choked up and truly knew who Dennis was.

His files are a Who's Who of tube audio history

Tuesday, April 28, 2020

ERC in the NY Times

Wednesday, November 27, 2019

Marantz 7T

The insides...

and in case you didn't notice, it happened to be sitting on by far the most beautiful piece of gear ever.

Friday, September 20, 2019

Sid Smith's ESL speaker

Apparently a successor to this speaker was shown by Joe Grado at the 1968 Philadelphia Audio Show and in today's dollar it would have been a $5700. It is unclear whether that id for a single or a pair but even at double it is still a fraction of what the market commands today.

dave